Over 30 million motors are sold each year for industrial purposes alone. In China, about 70% of the electricity consumption is in the industrial field, and the power consumption of industrial electronic motors accounts for 70% of the total electricity consumption in the industrial field. The Chinese government pushes on the new technology in the field of new energy,and emphases a number of products with high efficiency, energy saving and environmental protection.

Customers need new, high-quality products and require faster delivery of products. In addition, Electric motors companies must constantly improve productivity with less energy and resources against with increasing cost pressures.Competition among electric motor companies is fierce.Electric motor manufacturers have been innovating and improving efficiency. They focus on the research and development of powerful motors for every use. The newest report of top 20 electric motor manufacturer in the world 2018 shows that Siemens has grown into one of the world’s leading electric motors manufacturers. The Siemens try new approaches to overcome new challenges in drive technology. One of new ways is using

oxyhydrogen generators to replace traditional oxy-fuel.

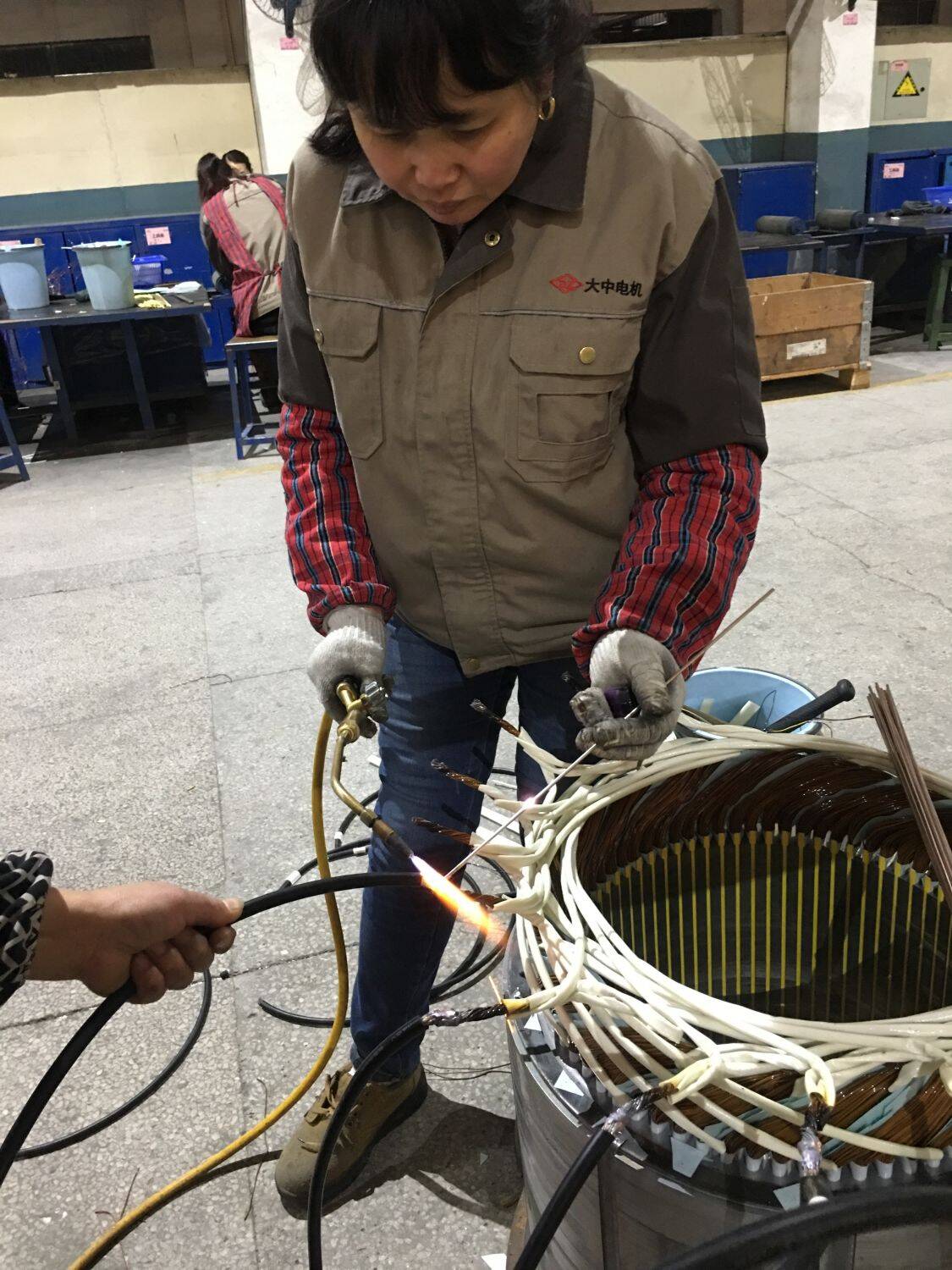

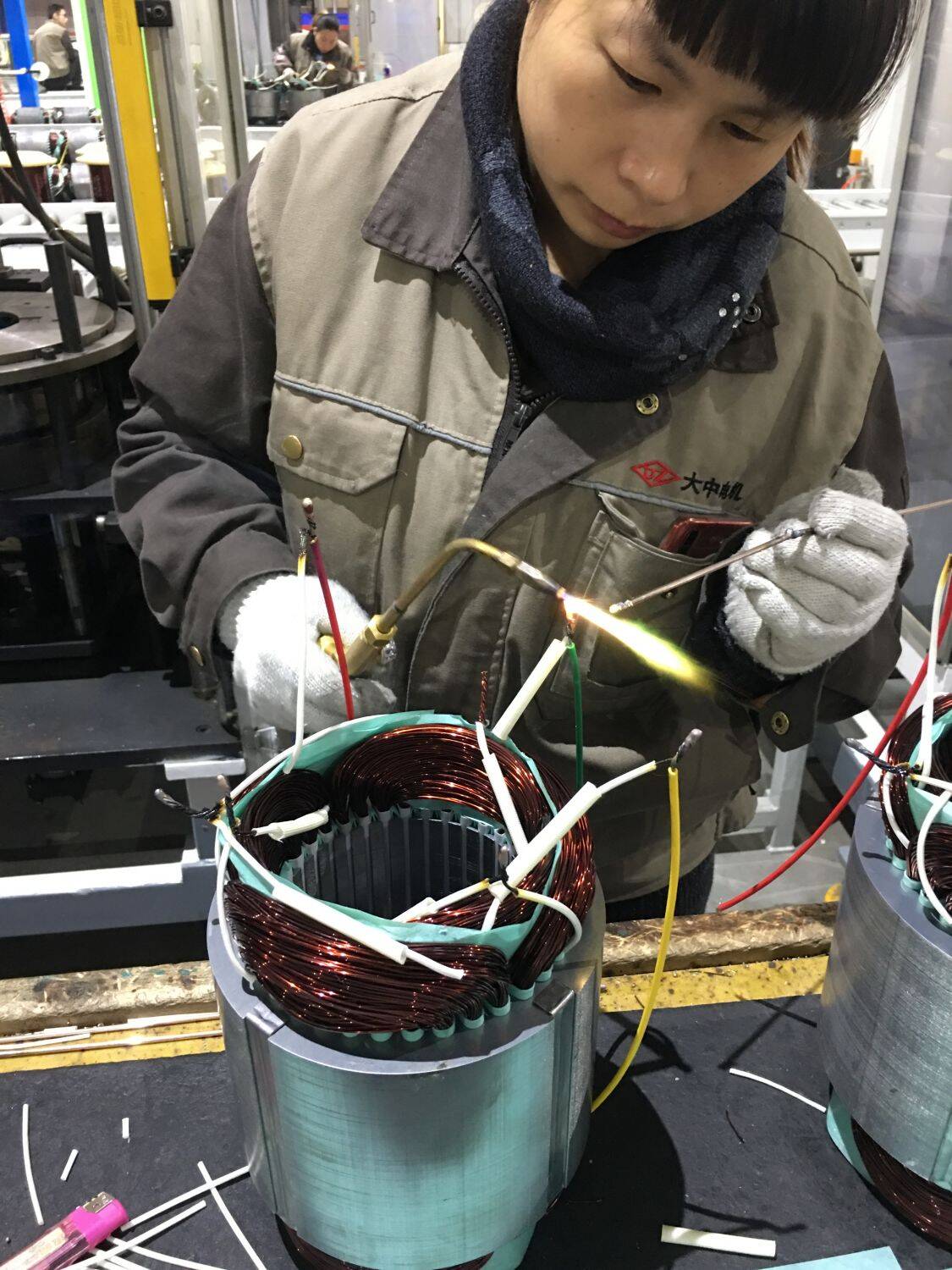

The conventional brazing technology is with gas cylinders(i.e. oxy-acetylene, oxy-propane or oxy-natural gas) in electronic motors,which takes more production time to remove the copper enamel coating from magnet wire. At the same time,It is harmful to human body and easy to cause safety accidents. The newest brazing technology only consume pure water and some electricity into oxygen and hydrogen gas on demand. It is clean energy ,eco-friendly to the environment and workers.

Okay Energy gas generators make brazing activities easier and safety for not skilled welders.”said Mr Tang, Dazhong technical engineer. Many of leading electronic motors manufacturers like Siemens,DZ accept oxyhydrogen generators to improve brazing technology in the process of soldering electric motor windings. Nowadays, this technology is used by the majority of electric motor producers, which is a big success that marks Okay Energy as an important partner.