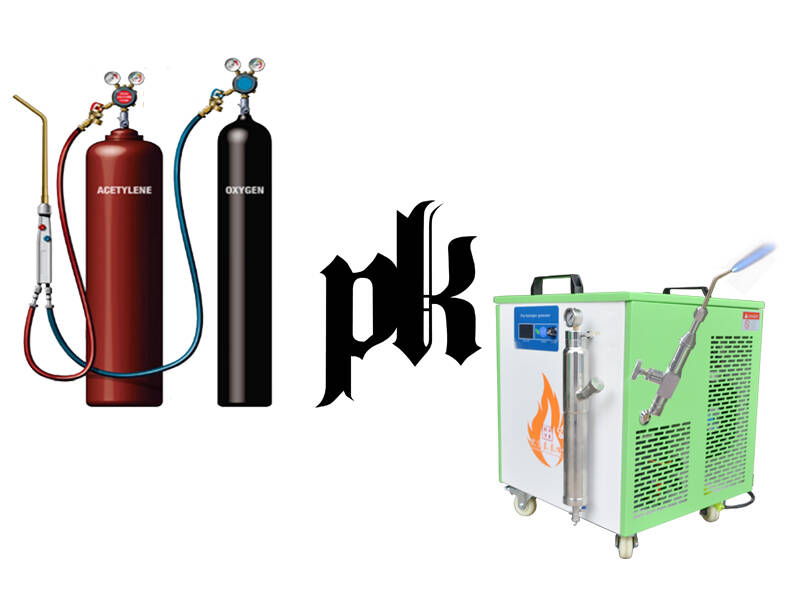

As welding and cutting operators,you should know the safe welding & cutting with oxy-fuel depending on proper and responsible use of oxy-fuel equipment. However,oxy-hydrogen is not gas storage and produce gas when machine power on.Why do you not try safety device oxy-hydrogen generator?

Oxy-fuels for welding and cutting

The most widely used gases is acetylene in work area.Because of its nature, always use and store the acetylene cylinder in an upright position, and never use acetylene above 15 lbs. pressure. Acetylene has a tendency to disassociate above 15 PSI, which can cause a chemical reaction.Other fuels are commonly referred to as “alternate fuels.” These include LP gases (propane, propylene and butane) and compressed gases such as natural gas and methane.(refer to article "The Keys to Oxy-Fuel Safety")They are a type of gas storage with a risk of gas explosion.

Oxy-hydrogen for welding and cutting

Oxy-hydrogen is no gas storage and produce mixture oxygen and hydrogen with 1:2 as you need.And oxy-hydrogen gas is odorless and clean gas.On the point of cost,it only consume some water and electric.Therefore,oxyhydrogen is widely used for jewelry welding,fishhook welding,copper wire welding,alumnium welding,brass instrument brazing,copper pipe brazing,sheet metal cutting etc.