1. The whole line meets new GMP requirements, and the cleaning effect meets the new Pharmacopoeia standards and requirements;

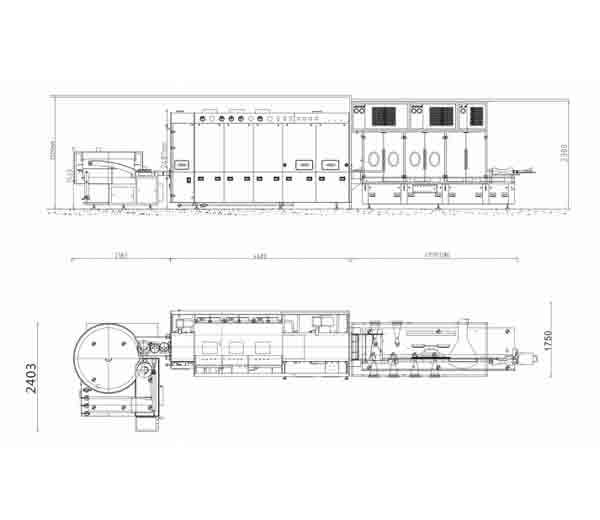

2. The whole line can adopt straight line layout or wallto-wall-shaped layout to reduce risk of cross-contamination and ensure aseptic level;

3. Applicable specifcation: 1ml-20ml ampoule (as per user's requirement);

4. Production Capacity:12000-36000BPH;

5. Number of filling head: 2-20, to be selected according to output;

6. Filling Accuracy:≤+1% (according to drug characteristics);

7. Choice of various filling pumps: glass pump, metal pump, peristaltic pump, ceramic pump;

8. Compact and simple structure, occupies less area;

9. Stable product performance, easy and reliable operation, beautiful appearance;

10.High degree of automation, fewer operators required;

11. Various sealing gas supply methods such as natural gas or hydrogen and oxygen gas;

12. Optional real-time display and printing system of sterilization temperature;

13. The maximum sterilization temperature of hot air circulation tunnel oven is 350°C;

14. The heat in the hot air circulation tunnel ovenis evenly distributed, and the heat resources removal effect is good;

15. Optional open-RABS isolation protection system and class 100 laminar flow hood protection;

16. Optional high-performance no-bottle-no-filling function and squeeze stop function;

17. The fiing machine can be equiped with onine monitoring system to monitor key factors that afect product quaity (such as dust partidles, planktonic bacternia,wind speed,wind pressure,etc.);

18. Full-line linkage control and operation function;

19. To realze fulyautomatc control and monitor of produchion proces,high precision colored touch screen aperation monitonng,PLCautomatic control& automatc protechion, mainmachine frequency conversion speed regulation and other control technology are used;

20. Applicable for wide range of bottle specifications, and easy to replace mould;

21. The products can be customized according to customer's actual demand.