|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

Explosion limit |

|||||||||||||||

|

Gas |

Formula |

|

Specific gravity |

Ignition point(℃) |

(air) |

|||||||||||||||

|

|

|

|

|

|

(volume%) |

|||||||||||||||

|

Hydrogen |

H2 |

|

0.07 |

585 |

4 |

|||||||||||||||

|

Acetylene |

C2H2 |

|

0.88 |

335 |

2.5 |

|||||||||||||||

|

Propane |

C3H8 |

|

1.567 |

467 |

2.2 |

|||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||

|

Gas |

Reaction formula(preheating) |

Oxygen consumption for preheating |

|

|

(When 10L gas is used) |

|||

|

|

|

|

|

|

Hydrogen |

2H2+O2 |

2H2O |

5L |

|

Acetylene |

2C2H2+5O2 |

4CO2+2H2O |

25L |

|

Propane |

C3H8+5O2 |

3CO2+4H2O |

50L |

|

|

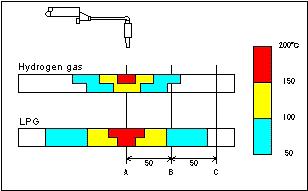

Hydrogen |

L P G |

Difference |

|

Oxygen |

34 |

43 |

9 |

|

LPG |

0 |

5 |

5 |

|

Power(facility driver) |

12 |

12 |

0 |

|

Power(hydrogen gas generator) |

4 |

0 |

4 |

|

Total |

50 |

60 |

10 |

The surface of cut edge is smooth and dross free, reducing or eliminating the secondary process should be changed to the surface of the cut edge is smooth and dross free, reducing or eliminating the need for secondary processing.

The surface of cut edge is smooth and dross free, reducing or eliminating the secondary process should be changed to the surface of the cut edge is smooth and dross free, reducing or eliminating the need for secondary processing. Conclusion

The hydrogen cutting method can meet environment friendly as well as energy saving requirements and therefore is expected to become a dominant welding and cutting method for steel in the future.Okay Energy have 4 models oxyhydrogen gas cutting system for choose according to the volumes of oxygen and hydrogen required.

|

|

Select from 4 models of gas generator according to the volumes of Oxygen & Hydrogen required. |

||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||