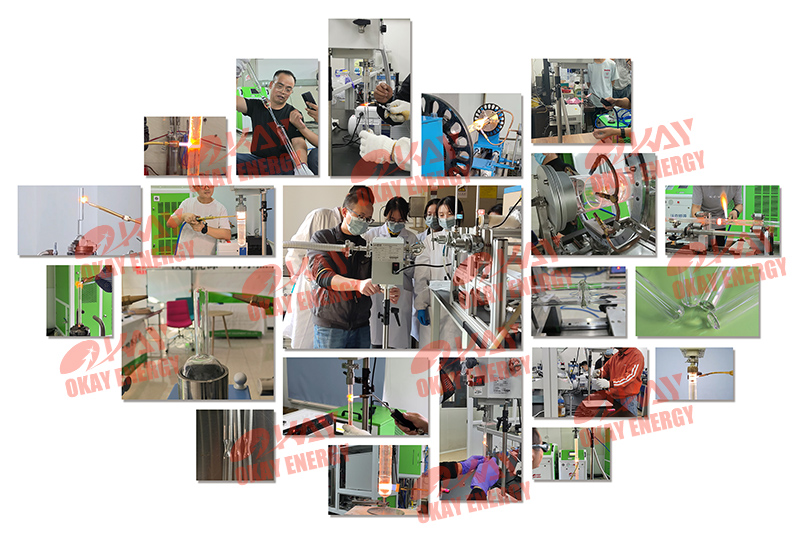

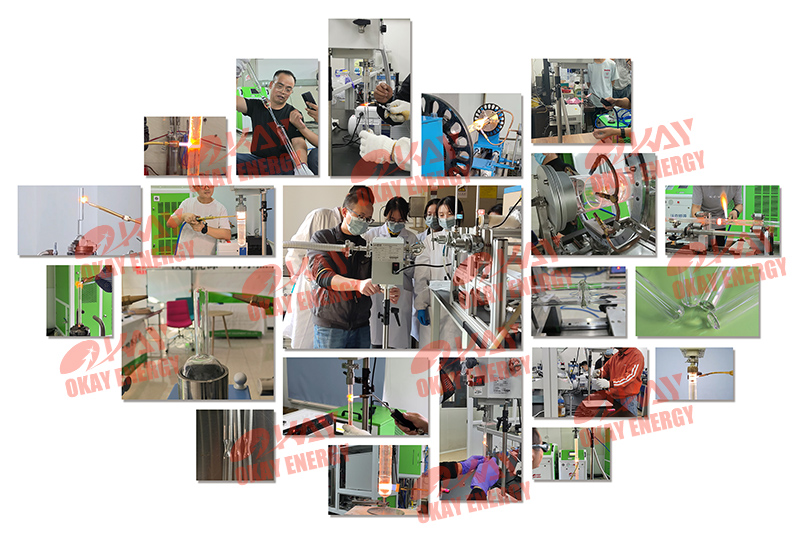

When sealing quartz tube, it is necessary to equip with industrial oxyhydrogen generators to melt glass tube fastly.Generally speaking,we suggest you choose the oxyhydrogen generators based on the the external diameter and thickness of glass tube.

|

Model |

OK-M210 |

|

Voltage |

220V 50/60Hz |

|

Name |

Rotary Quartz Vacuum Sealing Device |

|

Number of Workstation |

1 pcs |

|

Dimension-L*W*H(mm) |

300*240*690 |

|

Outer Diameter of Quartz Tube |

8-45mm |

|

Thickness of Tube Wall |

2mm |

|

Vacuum Joint |

KF25 |

|

Air Escape Valve |

KF16 |

|

Speeder |

LCD screen |

|

Optional Sealing Device |

Oxyhydrogen Generator,Vacuum Pump |