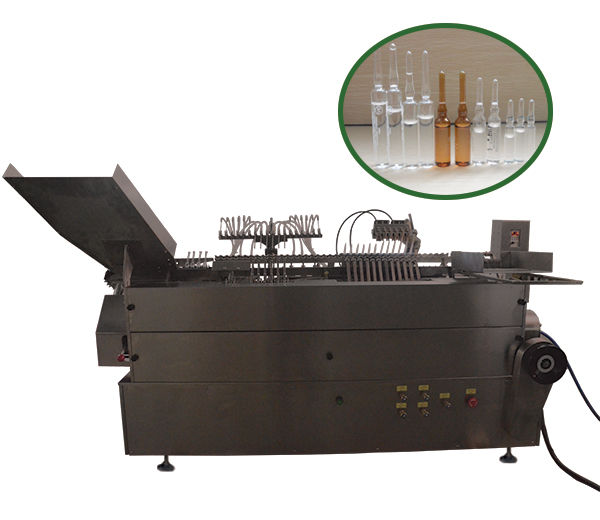

Pharmaceutical cosmetic automatic glass ampoule filling and sealing machine OKABFKJ-6

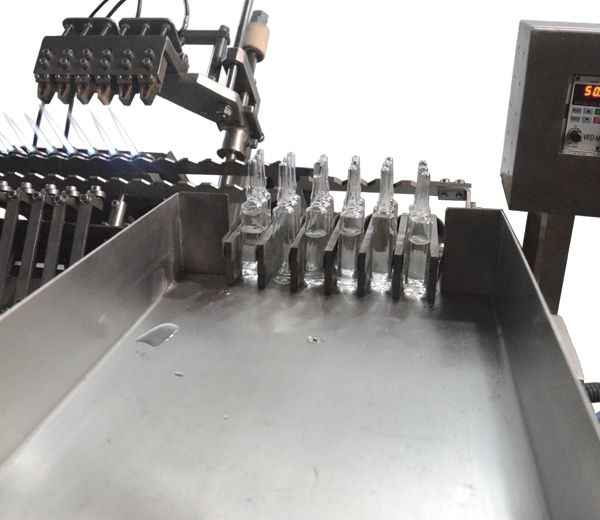

The machine adopted a rectangular bottle conveying mode with moving toothed plate at one time, and make the bottle stay on the fixed toothed plate for sufficient time, so as to improve the working efficiency of the whole machine.

Under the bottle feeding bucket, a clutch device is installed to stop the delivery of ampoules in the bottle hopper without stopping the machine, which is convenient for operation.

In ampoule drawing, steel wire rope is used to control manipulator to simplify the structure.

At the bottle outlet, the unique bottle turning structure is adopted, which straightens out the consistency between the movement direction of the mechanism and that of the bottle outlet, shortens the length of the machine and the space required by the workers, which is conducive to the layout of the user unit and the use of the site.

Oxyhydrogen flame ampule filling sealing solution

HHO technology uses water as medium to electrolyze water into H2 and O2, fire them to formed Oxyhydrogen Flame. The temperature of oxyhydrogen flame is as high as 2800 degrees so that it can seal the ampoules very fast. The quality and speed of Oxyhydrogen flame sealing method is higher than the traditional combustion-supporting coal,LPG gas,oxygen gas.

Recommend Oxy-hydrogen generator models OH1000,OH2000,OH3000 for automatic ampoule filling and sealing,which widely used in pharmaceutical,cosmetic industries.