Onion Skin Ampoule Filler Sealer Machine OKABFKJ-4

Onion skin ampoule filler sealer machine is designed for filling and sealing of onion skin ampoules and crushable glass ampoules. The equipment can ensure chemicals of high filling precision up to 1% into onion tubes. The matched fuel gas is alternative oxyhydrogen gas generator to replace the traditional gas cylinders.

HHO technology uses water as medium to electrolyze water into H2 and O2, fire them to formed Oxyhydrogen Flame. The temperature of oxyhydrogen flame is as high as 2800 degrees so that it can seal the ampoules very fast. The quality and speed of Oxyhydrogen flame sealing method is higher than Liquid gas's.The traditional combustion-supporting gas is coal,LPG,oxygen gas cylinder etc,there is a risk of explosion. Oxyhydrogen gas generator can completely replace gas cylinders, and it is simple and convenient for operation.

This machine provides optimum flexibility in the preparation of ampoules containing agro-insecticides, veterinary medicines, cosmetic ampoules and several other chemicals. This Filler Sealer is perfect for all kinds of open-mouth glass ampoules.

Technical Parameters

| Model |

OKABFKJ-4 |

| Available Heads |

four heads |

| Production Capacity(Bottles/Min) |

100 |

| Power Consumption(KW) |

0.5 |

| Onion Skin Tube |

Min diatmer 7mm~Mix height 55mm |

| Fuel Comsuption(m3/h) |

oxyhydrogen gas 2m3/h |

| Gas Capacity |

oxyhydrogen gas 2000L/h |

| Dimension(L*W*H-mm) |

2050*980*1350 |

| Weight(kg) |

450 |

Features of Onion Skin Ampoule Filler

1. Wide Range of Ampoule Size

Capable to handle minimum 7mm diameter ampoules with minimum height of 55mm.

2. Pre-heating

Pre-heating unit before sealing for perfect sealing of glass.

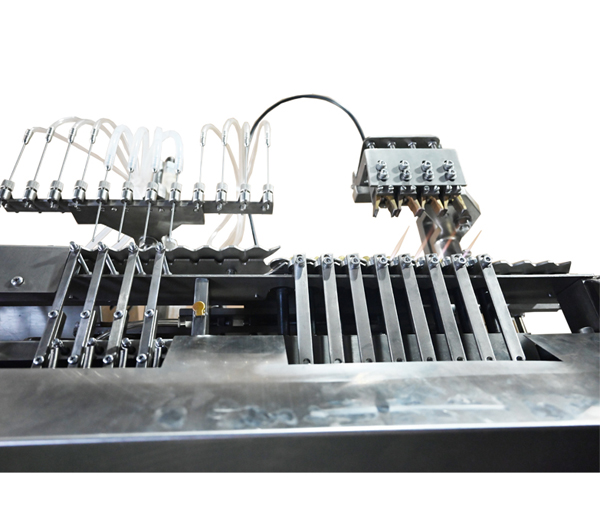

3. Designed Burner

Specially designed burners suitable for glass thickness of 0.3mm to 0.8mm.

4. Inlet Gas Flushing

Facility of flushing nitrogen/argon into ampules before and after filling.

5. Tips Colletctor

Tips collector made with the high quality stainless steel.

Related Accessories:

.jpg)