Details:

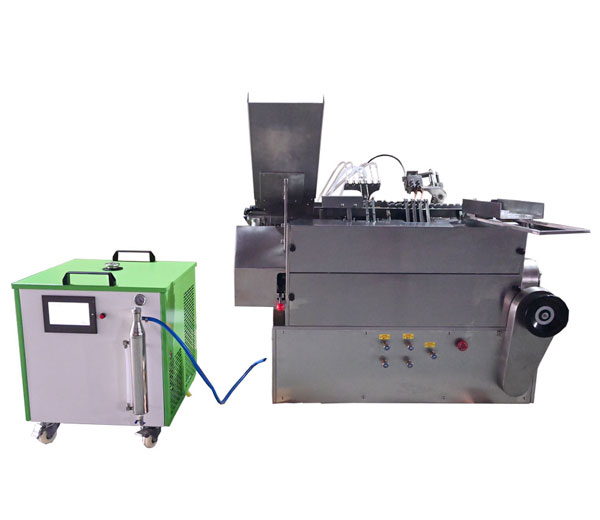

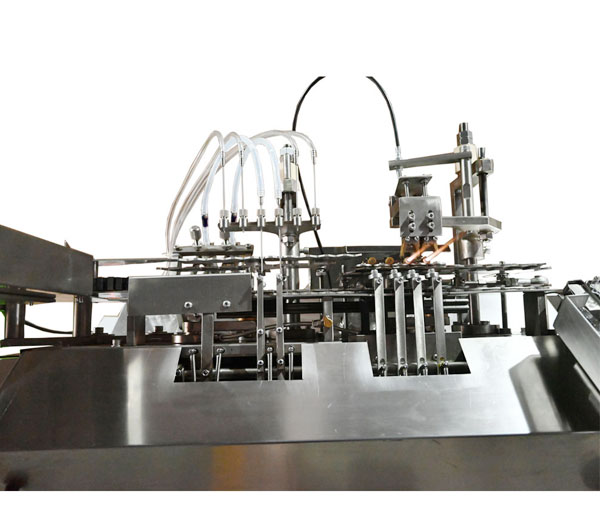

Automatic oxyhydrogen flame ampoule filling and sealing machine OKABFKJ2-1-2

Oxyhydrogen flame Ampoule Filling and Sealing Machine / Cosmetic Glass Ampoule Making Machine ' HHO technology uses water as medium to electrolyze water into H2 and O2, fire them to formed Oxyhydrogen Flame. The temperature of oxyhydrogen flame is as high as 2800 degrees so that it can seal the ampoules very fast. The quality and speed of Oxyhydrogen flame sealing method is higher than Liquid gas's.

The traditional combustion-supporting gas is coal,LPG,oxygen gas cylinder etc,there is a risk of explosion. Oxyhydrogen gas generator can completely replace gas cylinders, and it is simple and convenient for operation.

Okay Energy developed and designed two types of oxy-hydrogen generator for manual ampoule sealing and automatic ampoule filling and sealing.

Recommend Oxy-hydrogen generator models OH1000,OH2000,OH3000 for automatic ampoule filling and sealing,which widely used in pharmaceutical,cosmetic industries.

Technical Parameters:

|

Model

|

OKABFKJ2-1-2

|

|

Available Heads

|

single head/double head

|

|

Production Capacity(Pieces /Hour)

|

3600-3900

|

|

Power Consumption(KW/H)

|

0.55

|

|

Fuel Consumption(m3/h)

|

Coal gas 3-3.5m3/H or LPG 1.5-2m3/H,

combustion-supporting gas:oxygen;

Oxyhydrogen gas 1000LPH

|

|

Dimension(L*W*H-mm)

|

1200*980*1350

|

|

AC Voltage(V)

|

220/380V 50-60 Hz

|

|

Weight(KG)

|

250

|

Advantage characteristics:

Oxyhydrogen generator's features for ampoule filling and sealing

1.Safety

Oxy-hydrogen Flame Ampoules Sealing Machine just uses water and electricity, no gas bottle, no hydrogen gas storage, no leakage and explosive danger.

2.Convenience

it can work just with water and electricity, every litre water can be used 7~8 hours. But Liquid gas bottle need to be changed by manual moving, it is very inconvenient.

3.Cleanliness

Oxy-hydrogen combustion just produces little water vapour, there is no harm to the pharmaceuticals. But Liquid gas combustion produces carbon dioxide, carbon monoxide and nitrogen compounds which will impact on the quality of pharmaceuticals.

4. High Efficiency

The speed of Oxy-hydrogen Flame sealing method is higher than Liquid gas's.

Related Accessories: