.jpg)

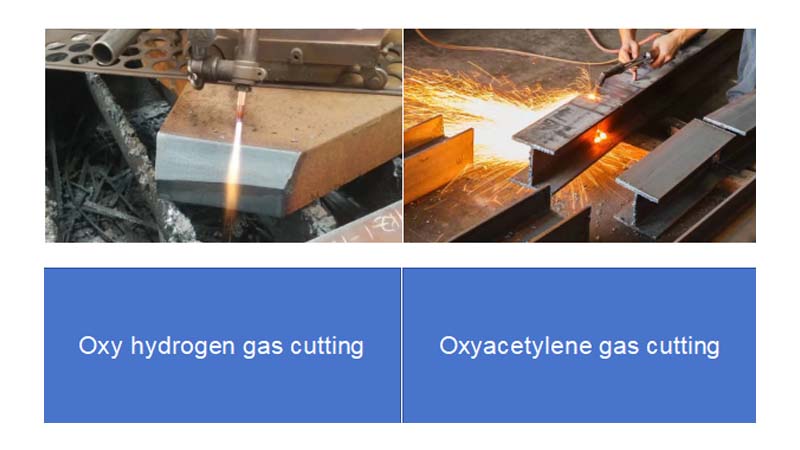

| Feature | Oxy-Hydrogen (HHO) | Oxy-Acetylene |

| Fuel Source | Water & Electricity | Calcium Carbide & Natural Gas |

| Operating Cost | Very Low (after initial investment) | High (recurring cylinder costs) |

| Safety | High (non-toxic, on-demand generation) | Moderate (flammable, explosive, stored under pressure) |

| Environmental Impact | Zero CO₂ Emissions | High CO₂ & Carbon Monoxide Emissions |

| Flame Temperature | ~3000°C | ~3100°C |

| Cutting Mechanism | "Vaporization" - produces a clean, oxide-free cut. | "Burning" - can oxidize the metal edge. |

| HAZ (Heat-Affected Zone) | Smaller | Larger |