Oxyhydrogen Gas Welding Machines in the Jewelry Industry

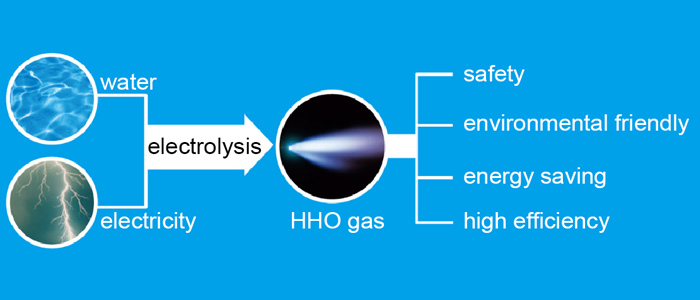

In the modern jewelry manufacturing industry, precision, aesthetics, and environmental responsibility are becoming more important. In recent years, Oxyhydrogen gas welding machines, also known as water gas welders or HHO welders, have emerged as an efficient, clean, and precise alternative, particularly suitable for jewelry fabrication and repair.

More +