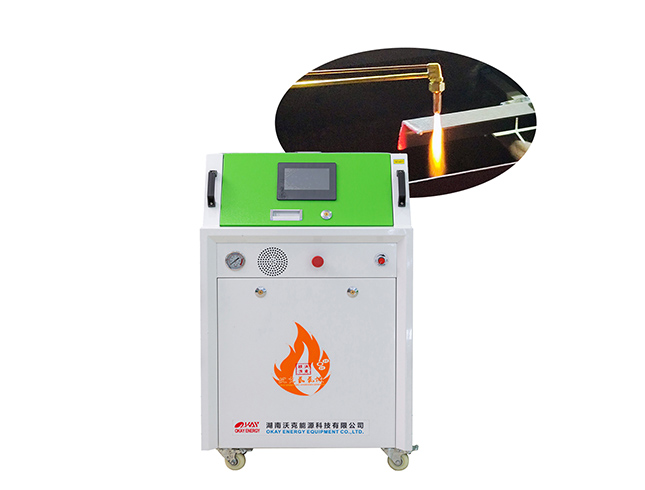

Oxyhydrogen cutting technology revolutionizes industrial metal cutting with its exceptional efficiency and eco-friendly operation. Its concentrated 3000°C flame delivers precise, clean cuts through various metals including carbon steel and non-ferrous alloys, with minimal thermal distortion. Enhanced safety features such as flashback arrestors and pressure monitoring systems ensure secure operation in demanding industrial environments. The technology offers 40-60% cost reduction compared to traditional methods while maintaining consistent cutting quality.

.jpg/Oxyhydrogen%20flame%20for%20Cutting(2)__800x449.jpg)