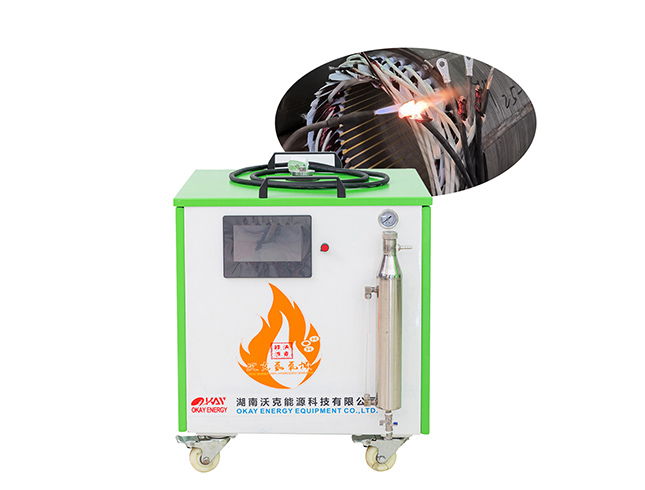

1.automatic ignition and flame out.

2.smart flame regulator for stable oxyhydrogen flame.

3.intelligent anti-backfire technology with electronic flame arrestor.

4.PLC display panel system for easy operation.

5.customized flame torch and nozzles upon your demand.

6.Minimal resource consumption (water + electricity) cuts long-term expenses.

7.Uses water as fuel and emits only pure water vapor, ensuring zero pollution.

8.Operation with no gas storage eliminates explosion risks.

9.Produces a concentrated flame up to 3000°C, ideal for precise welding and brazing tasks.