Details:

The disadvantages of traditional ampoule sealing machine Traditional ampoule sealing machine adopts liquid gas as fuel and air as combustion-supporting gas.The produced flame contains carbon dioxide,carbon monoxide and nitrogen compounds.These substances will impact on the quality of pharmaceuticals and bring hidden dangers to working environment.

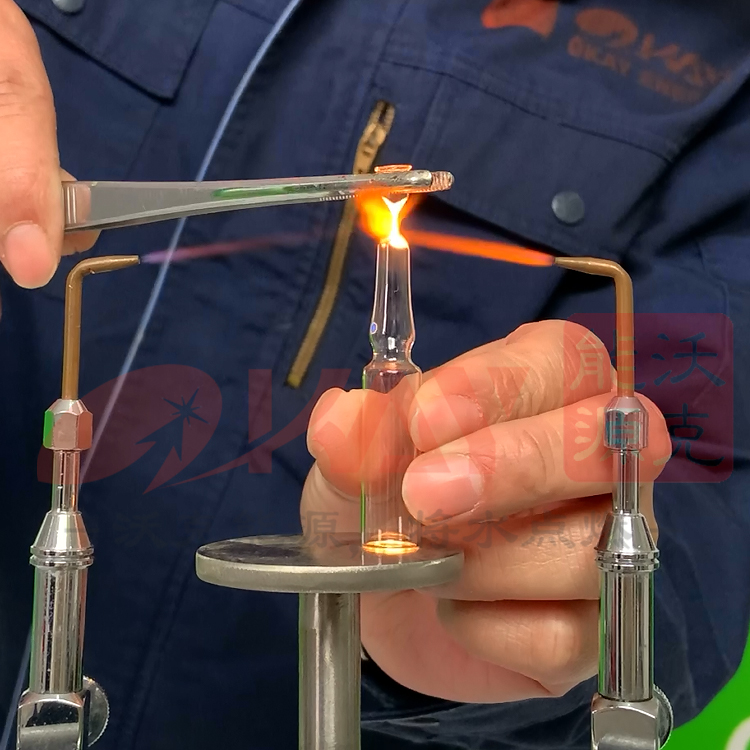

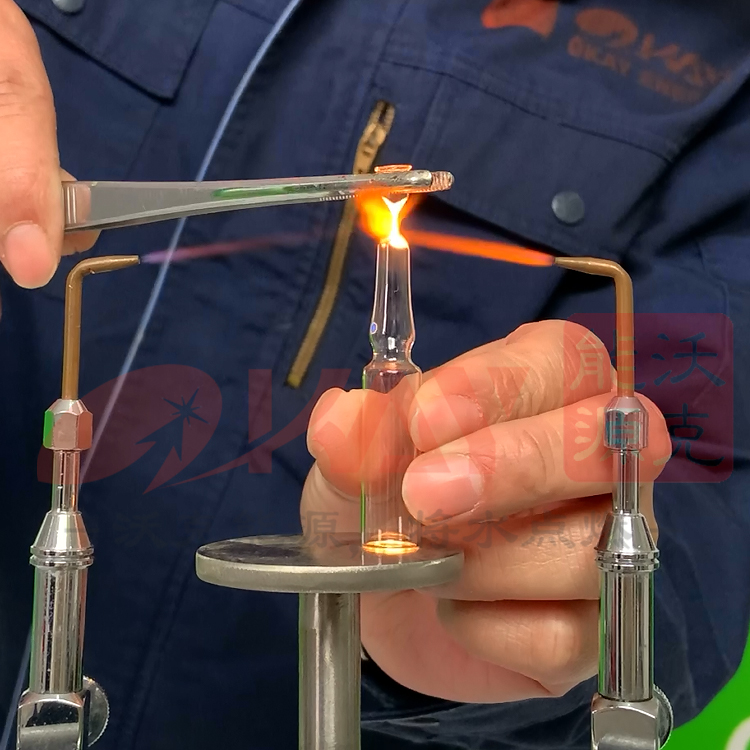

Oxyhydrogen generator uses water as medium to electrolyze water into H2 and O2,and fires them to form oxyhydrogen flame.The temperature of oxyhydrogen flame is as high as 2800 degrees so that the oxyhydrogen sealing effect and speed is higher and faster than traditional oxyfuel gas for ampoule sealing.

Technical Parameters:

|

Model Number

|

OH300

|

|

AC Voltage Requirement(V)

|

220/110

|

|

Phase

|

single

|

|

Power Consumption(kw/h)

|

1

|

|

Max. Gas Output(L/h)

|

300

|

|

Max. Working Pressure(Mpa)

|

0.14 |

|

Max. Water Consumption(L/h)

|

0.17

|

|

Water Feed

|

manual

|

|

Flame Modifier Feed

|

manual

|

|

Dimensions-L*W*H (mm)

|

575*246*470 |

|

Weight(kg)

|

23

|

|

Ventilation Space Requirement(mm)

|

200 in each direction

|

Ultra-Clean Flame: Produces only water vapor upon combustion, ensuring a contamination-free seal critical for pharmaceutical integrity.

Precise, High-Temperature Flame: Achieves over 3000°C for fast, localized melting without thermal damage to the bottle or its contents.

Enhanced Sealing Quality: Creates a uniform, strong, and bubble-free seal, drastically reducing leakage rates.

Superior Operational Safety: Generates gas on-demand with no need for high-pressure gas cylinder storage.

Excellent Process Control: Allows for fine adjustment of flame intensity and size for consistent, repeatable results.