The concentrated 3000°C flame enables precision welding and brazing of non-ferrous metals including copper, brass and aluminum alloys, with zero oxidation and minimal heat-affected zones. Integrated safety systems with multiple protection mechanisms ensure reliable operation in high-volume production environments.

Ideal for metal fabrication, electrical component manufacturing, and precision equipment repair, our solutions reduce operational costs while maintaining consistent weld quality. Designed for continuous industrial use, these systems deliver the reliability and performance demanded by modern manufacturing facilities.

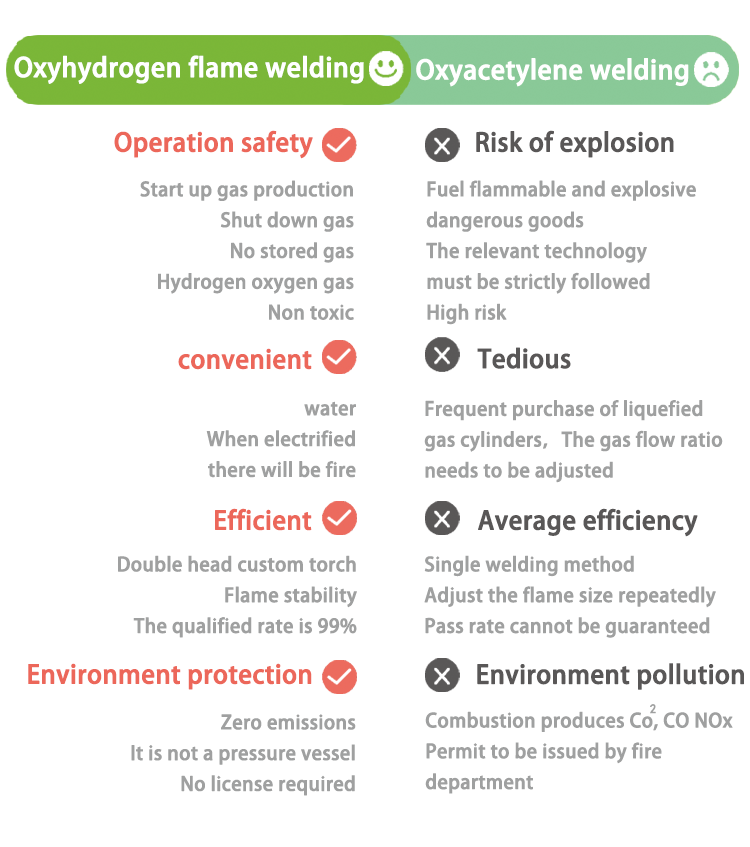

Oxyhydrogen flame for welding:

1.Safety. no gas bottles. and no gas leakage or explosion.

2.Convenient. 24hours continous running working.Only consume some water and electricity.

3.Clean. Oxyhydrogen flame burns without Co2, Co and NOx.

4.High efficiency. the welding speed is fast than the traditional liquid gas.