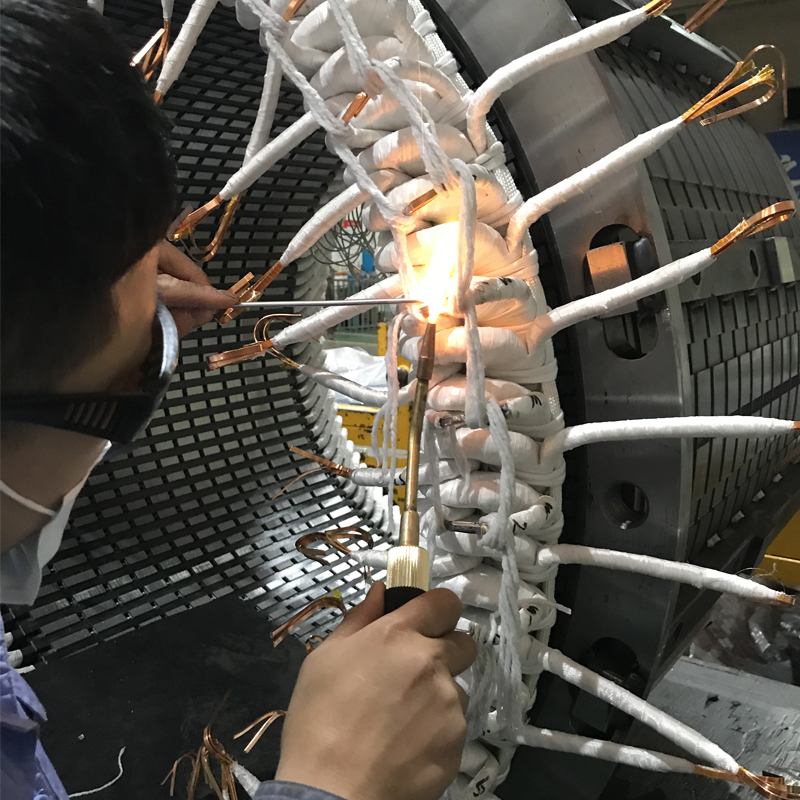

The oxyhydrogen welder offers a clean, eco-friendly flame from water electrolysis. It requires no gas cylinders and produces only water vapor. Its concentrated 3000°C flame ensures precise, oxidation-free welding on non-ferrous metals like copper and silver. Multiple safety features guarantee secure operation. Ideal for jewelry, copper, aluminum, electronics, and HVAC repair.

Okay Energy Oxyhydrogen welding features:

1.no explosion,safety (low pressure and zero storage)

2.non-toxic and no pollution(no smoke,only water vapor after combostion)

3.energy saving 40-60%

4.20% higher efficiency

5.exceptional precision(concentrated flame)

6.low operational cost(using only electricity and water)

Oxyhydrogen flame ideal for welding industries:

1)OEM, transformers and power generators;

2)electric motor and power generator repair shop;

3)electric motor work shops;

4)large air conditioning supplies;

5)solar collectors;

6)manufacturing of large statues;

7)manufacturing of trophies, chandeliers, statues and other brass articles etc;

8)gold silver platium jewelry welding and repair;

9)musical instrument welding & repair;

10)others copper welding & soldering