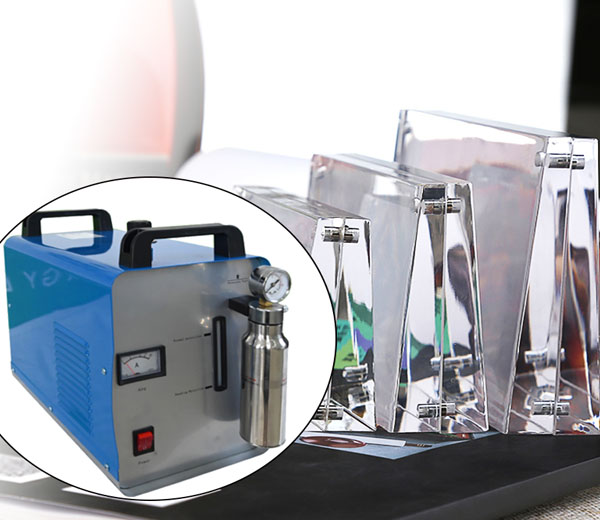

Why do you use oxy-hydrogen for acrylic flame polishing ?

The oxy-hydrogen flame acrylic polishing machine offers a pristine, high-temperature flame perfect for acrylic polishing. It ensures no carbon residue and precise control, makes acrylic edge smooth and bright, enhancing both efficiency and final product quality.

.jpg)

Technical Parameters:

|

Model Number

|

SOH100

|

|

Type

|

conventional type

|

|

AC Voltage Requirement(V)

|

220/110

|

|

Phase

|

single

|

|

Power Consumption(kw/h)

|

0.35

|

|

Max. Gas Output(L/h)

|

100(adjustable)

|

|

Max. Working Pressure(Mpa)

|

0.14

|

|

Max. Water Consumption(L/h)

|

0.06

|

|

Water Feed

|

manual

|

|

Flame Modifier Feed

|

manual

|

|

Dimensions-L*W*H (mm)

|

390*250*510

|

|

Gross Weight(kg)

|

11

|

|

Ventilation Space Requirement(mm)

|

200 in each direction

|

Advantage characteristics:

Advantage characteristics:

1.Easy and safety operation

It produce oxy-hydrogen gas by automatic way as you required. Machine will shut down automatically when the gas pressure is too high

2.Welding fast

The oxy-hydrogen flame temperature is high up to 2800 degree, it can heat the welding spot to melting point fast in about 1 second to finish welding.

3.Welding precisely

The flame is concentrated, it can achieves welding of precise devices.

4.Smooth welding spot

Oxy-hydrogen flame combustion doesn't form carbide, so there is no black spot, avoid the second treatment of cleaning and polishing.

5.Environment friendly

Oxyhydrogen welding machine 's fuel comes from water.

There is water vapor after combustion.No harm to environment.

6. Energy saving

oxyhydrogen generator saves energy cost over 30% compared with other gas welding way.Adding the oxygen cost, it will save cost over 40%.

.jpg)

.jpg)